Abstract

Objective: To

simultaneously assess the rate of aerobic bacteria, yeast-mold proliferation

count in 2 red delicious apple sections from a parent

apple specimen, with and without proximal exposure to a packet of

Zeolite-coated Potassium Permanganate (Z-KMnO4). (Note: This

is a plastic louvered container enclosed sachet filled with Potassium

Permanganate,

KMnO4.)

Design, Sample, Location: Following

28-days' refrigeration in

separate compartments, two "Red Delicious" apple samples

excised from a single specimen were reduced to 1:1000 solutions then

incubated for 36 and 72 hours to determine aerobic bacteria and yeast-mold

counts respectively, in Northeastern Washington. One sample was exposed

to an antimicrobial mineral compound, Z-KMnO4, while the other sample

was isolated (compartment-separated) from the antimicrobial Z-KMnO4

mineral compound.

Results: Harvested apples predictably release ethylene gas, which acts

as a ripening hormone. As ripening progresses, commensal environmental

microbes proliferate in samples exposed to air. Eating over-ripened,

microbe-infected spoiled produce has been associated with severe gastric

stress, compromised immunity, and allergic reactions. The spoilage

rate of stored produce is dependent upon time, temperature, viscosity,

pH, humidity, space, and nutrient access. Refrigeration in temperatures

below 50 degrees F and under 45% humidity delays the rate at which

produce deteriorates by inhibiting ethylene gas ripening hormone release,

hence the rate at which aerobic bacteria, yeast, and mold grows in

produce. Zeolite-coated Potassium Permanganate (Z-KMnO4) placed proximal

to refrigerated produce reduces ripening rate, inhibits microbial growth,

and spoilage. Identifying which microbes and how many are inactivated

by packets of Z-KMnO4 in refrigerator compartments, until now, has

not been identified. A randomly selected Red Delicious apple sample

was refrigerated for 28-days and enclosed adjacent to a single Z-KMnO4

packet. This sample, following incubation, yielded 10,000 aerobic bacteria

per milliliter count. Simultaneously, an apple section from the same

apple was refrigerated for 28-days without Z-KMnO4 exposure. This sample

yielded a count of 10,000,000 aerobic bacteria per milliliter. From

the same Red Delicious apple sample, both sections after being refrigerated

for 28-days surprisingly yielded an equal ratio of 100,000 yeast/mold

per milliliter in the sample with Z-KMnO4, and 100,000 yeast/mold per

milliliter in the sample isolated from exposure to Z-KMnO4.

Conclusion: This shows that a single packet (Z-KMnO4) stored with a

refrigerated apple sample reduced the aerobic bacteria (AB) proliferation

growth count by a factor of 1000, (10,000 AB Z-KMnO4) as compared to

10,000,000 AB non-exposed sample). However, Z-KMnO4 exposure did not

reduce yeast/mold growth in either sample (100,000 Z-KMnO4 as compared

to 100,000 in non-exposed sample). Given the cost to health from incidental

consumption of spoiled produce, reducing the rate of aerobic bacteria

growth in produce is a nutrient-protective intervention with disease-preventative

implications. This single experimental study is conclusively limited

and therefore requires more extensive research in order to explain

or confirm the evidence reported.

Introduction

Ethylene Gas (C2H4), a hydrocarbon, is a natural product of plant metabolism

and is produced by all tissues of plants as a hormone, increasing

the rate of aging and ripening properties. Harvested apples

release significant amounts of ethylene,

a hormone-ripening agent. During the ripening stage of fruit,

ethylene gas accelerates the maturity

process. Ethylene gas (released at a very high rate from

apples)

accelerates ripening, loss of chlorophyll, abortion of plant

parts, stem shortening, abscission of plant parts, and epinasty

(Han JH,

2003).

Apple Rate of Ethylene Production

| Temperature |

0°C (32°F) |

5°C (41°F) |

10°C (50°F) |

20°C (68°F) |

| µ 1/ kg·hr |

1–10 |

2–20 |

5–40 |

20 –125 |

Higher rates for riper apples.

From: Postharvest Technology Research and Information Center, Department

of Pomology; University of California, One Shields Ave., Davis, CA

95616-8683.

By permission, courtesy of Dave Biswell, President, Ethylene Control

Inc.

(559) 896-1909; (800) 200-1909; www.ethylenecontrol.com

Apple 'Red Delicious' Recommendations for Maintaining Postharvest Quality

http://www.ethylenecontrol.com/technical/uc105.htm

Table V.

How Ethylene Gas Affects Produce

(Ethylene production and sensitivity levels in selected fresh produce)

Fruits & Vegetables

Types

|

Rate of Ethylene |

Ethylene Sensitivity |

Principal Reaction to Ethylene Gas |

APPLES

Apricots

Asian Pears

Asparagus

Avocados

Bananas

Berries

Broccoli

Brussel sprouts

Cantaloupe

Carrots

Cherimoya

Cherries

Cucumbers

Eggplant

Grapefruit

Grapes

Kiwifruit

Lemons, Limes

Lettuce (2)

Mangoes

Melons (3)

Nectarines

Onions, Garlic

Oranges

Papaya

Passion Fruit

Peaches

Pears (5)

Persimmons

Plums, Prunes

Potatoes (6)

Quinces

Tomatoes

Watermelons |

VH

H

H

VL

H

M

L

VL

VL

H

VL

VH

VL

L

L

VL

VL

L

VL

VL

M

M

H

VL

VL

H

VH

H

H

L

M

VL

L

M

L

|

H

H

H

M

H

H

L

H

H

M

L

H

L

H

M-H

M

L

H

M

H

H

H

H

L

M

H

H

H

H

H

H

M

H

H

H |

SCALD(1)

Decay

Decay

Toughness

Decay

Decay

Mold

Yellowing

Yellowing

Decay

Bitterness

Decay

Softening

Yellowing

Brown

Spots

Mold

Mold

Decay

Mold

Russet spotting

Decay

Decay

Decay

Odor, sprouting

Mold

(4)

Decay

Decay

Decay

Decay

Decay

Decay

Sprouting

Decay

Shrink, decay

Lose

firmness |

Table V Notes:

VL

= Very low

L = Low

M = Moderate

H = High

VH = Very High

(1) Lose

crunch

(2)

Leafy greens

(3) Crenshaw, Honeydew, Persian

(4) Rind breakdown

(5)

Anjou,

Bartlett, Bosc

(6) Processing, Seed

Fresh Produce Manual for

1997 from

the Produce Marketing Association and the 1991 Sea Land Shipping

Guide

for Perishables. By permission, courtesy

of Dave

Biswell, President, Ethylene Control Inc. 559-896-1909; 800-200-1909; www.ethylenecontrol.com

Following harvest, apple produce commences to release ripening-hormone

ethylene gas. Over-ripening reduces the shelf life of apples, and so

the reduction of ethylene is necessary. Ethylene gas removers include

potassium permanganate (KMnO4), zeolite, clay, bentolite, alumino-silicate

and active carbon. Other sources of ethylene include ripening fruit,

rotting vegetation, exhaust from internal combustion engines/heaters,

smoke (including cigarettes), welding, and natural gas leaks (Han JH,

2003).

As fruit ripens, the fluid-juice within the fruit body supports aerobic

bacteria and yeast/mold proliferation. Food-borne illnesses may occur

due to incidental consumption of commercial, nonpasteurized ("fresh" or "unpasteurized")

fruit juices (Matthys AW). Nonpasteurized fruit juice has been associated

with numerous food-borne illness outbreaks since the 1920s. Disease

syndromes have included salmonellosis, typhoid fever, cryptosporidiosis,

Escherichia coli-related diarrhea, and hemolytic uremia (Parish 1997).

Apple Juice-associated Food Poisoning Outbreaks

| Juice Product (Year) |

Infectious Agent |

Sweet cider (1923)

Apple cider (1974)

Apple cider (1980)

Apple cider (1991)

Apple cider (1993)

Apple cider (1993)

Apple juice (1996)

Apple juice (1996)

Apple juice (1996)

Apple cider (1997)

Apple cider (1998)

Apple cider (1999)

|

Salmonella typhi

S. typhimurium

Enterotoxigenic E. coli

E.coli 0157:H7

E.coli 0157:H7

Cryptosporidium spp

E.coli 0157:H7

E.coli 0157:H7

Cryptosporidium parvum

E.coli 0157

E. coli 0157:H7

E. coli 0157:H7 |

Table Notes: Parish ME.1997. Public

health and nonpasteurized fruit juices. Crit

Rev Microbiol 23(2):109-19; Bates R.P.,

Morris J.R., Crandall P.G. Principles and practices of small - and medium -

scale fruit juice processing, FAO Agricultural

Services Bulletin 146. FAO 2001. (See

Chapter 4 table.) Beuchat LR, Nail BV, Adler BB, Clavero MR. Efficacy of spray

application of chlorinated water in killing pathogenic bacteria on raw apples,

tomatoes, and lettuce. J

Food Prot. 1998 Oct;61(10):1305-11.

Aerobic bacteria, E. coli 0157:H7, L. monocytogenes, and Salmonella proliferate

in apple juice. Escherichia coli 0157:H7, Listeria monocytogenes, and

Salmonella have been detected in samples of apple, orange, pineapple,

and white grape juice concentrates even after 12 weeks of storage at

-23 degrees C (Oyarzabal et al., 2003). Yeast, mold fungi, lactic-acid

bacteria, and cocci log growth rate parallels deterioration of fruit

juice represented by spore mesophyll aerobes of the subtilis-mesentericus

type (Slovachevskaia et al., 1988). Pasteurization of apple cider is

therefore a validated treatment for ensuring adequate destruction of

E. coli 0157:H7, Salmonella spp., and L. monocytogenes (Mak et al., 2001,

Teo et al., 2001).

Preventing microbial infection of whole fruit is unavoidable. In three

field studies, samples of unwashed apples (drops and picked), washed

apples, and freshly pressed cider were presumptively analyzed for total

coliforms, E. coli, and enterococci using qualitative and/or quantitative

methods. Drop apples were more likely than picked apples to be contaminated

with E. coli (26.7% vs. 0%) and enterococci (20% vs. 0%). Washing had

little effect on coliform populations and in one field study was associated

with increased numbers. Total coliform populations in cider ranged

from <1

CFU/ml to >738 most probable number/ml, depending on the enumeration

method used and the sample origin. E. coli was not recovered from washed

apples or cider, but enterococci were present on 13% of washed apple

samples. The qualitative coliform method successfully detected these

bacteria on apples and in cider. Based on its exclusively fecal origin,

good survival in apple cider, and association with drop apples, research

concludes that E. coli is the most useful organism for confirming apple

and cider sanitation (Lang et al., 1999).

Reducing either the regeneration rate of commensal microbe proliferation

as apples ripen or reducing the rate of ripening without toxically

affecting the nutrient profile of the fruit using Zeolite-coated Potassium

Permanganate

(Z-KMnO4) in an enclosed packet was examined. Potassium

Permanganate (KMnO4) is a mild antiseptic/astringent, with

antimicrobial properties

(Anderson 2003). One study quantified the inactivation of the endotoxin

derived from Escherichia coli 055:B5 by Potassium Permanganate (KMnO4)

used as an oxidant in drinking water treatment and was shown to inactivate

1.0 endotoxin units (EU)/mLh derived from Escherichia coli 055:B5 (Anderson

et al., 2003). It was reported that potassium permanganate inactivated

90–100% of Pasteurella multocida strains (Karaivanov 1976, Brown

et al., 1978). The Salmonaella enzyme was observed to be oxidized/inactivated

by exposure to Potassium Permanganate (Roberts et al., 1975). Even

the highly resistant virus of Creutzfeldt Jakob disease, exposed to

a preparation

of potassium permanganate, is either inactivated or inhibited (Uysal & Kaaden

1993).

In a preliminary investigation, I excised 2 Red Delicious apple sections

from the same apple and refrigerated them separately for 7 days. One

sample was exposed to Zeolite-Coated Potassium Permanganate (Z-KMnO4)

and the other sample was not exposed to Z-KMnO4. The Z-KMnO4 sample presented

no outward visible spoilage/deterioration effects while the non-exposed

sample displayed significant observable deterioration. What then was

the numerical antimicrobial effect from Z-KMnO4 on aerobic bacteria and

yeast/mold growth rate?

In the present investigation, I repeated the preliminary experiment,

but extended refrigerated storage from 7 to 28 consecutive days. Taken

from a parent apple specimen, one apple section was exposed to Z-KMnO4

but not the other. Aerobic bacteria growth rate in the Z-KMnO4 exposed

sample was significantly inhibited (by a factor of 1000 X (10,000 AB/ml

Z-KMnO4 sample to 10,000,000 AB/ml non-exposed sample). It was further

observed that Z-KMnO4 did not inhibit Yeast/Mold (YM) growth.

Both samples following 28 days refrigeration yielded no significant difference

in

YM count/ml (Z-KMN04 = 100,000/ml YM: non-exposed sample = 100,000/ml

YM).

Materials and Methods

Red Delicious Apples. Random selected

produce was purchased from a Supermarket, Safeway Food & Drug,

1616 Northwest Blvd., Spokane, Washington, 99205.

Aerobic Bacteria and Yeast/Mold Test System Kits. Biosan Laboritories

donated a SaniCheckAB and a SaniCheckYM Test System For Counting

Aerobic Bacteria and Yeast/Mold. Biosan Laboratories, Inc.,

1950 Tobsal Court,

Warren Michigan, 48091–1351.

Zeolite-coated Potassium Permanganate (Z-KMnO4) packets

were donated by WayChem INC, P.O. Box 1450, 1101 Main Street, Evanston,

Wyoming,

82931.

Design

A single Red Delicious apple was randomly selected from a dozen specimens.

The outside of the apple was washed thoroughly with detergent soap

then washed again with a 1% solution of hydrogen peroxide (H2O2)

to inactivate transient microbes from the exterior skin surfaces.

The parent apple was sectioned into 25-gram and 28-gram samples,

respectively. Sterile technique was employed with all utensils prior

to placing samples inside two enclosed containers, one with a 7.5-gram

packet of Z-KMnO4 and one without. Both containers

were simultaneously stored in opposite refrigerator produce drawers.

Each refrigerated

compartment retained a consistent 45° F at 40% humidity for this

28-day storage period. After 28-days, each slice was blended in a

distilled water 1:10 solution then further triturated to 1:1000 solution.

Each solution's microbial count was determined by application

of a SaniCheckAB and SaniCheckYM test pad to each sample. Each sample

was incubated at 25–30°C (77–86°F) for either

36 hours for aerobic bacteria count or 72 hours for Yeast/Mold

count, respectively.

Results

When the phenolic compound in each

apple sample was exposed to air, a

predictable MaillardReaction,

browning of the fruit occurred at a more rapid rate in the control

sample than in the VCPP sample (See

Table I) or pictured example from a Gala Apple sample. In isolated

refrigeration compartments, aerobic bacteria growth within an

enclosed Red Delicious apple sample was inversely associated

with proximal

effective exposure to a single 7.5-gram packet containing Z-KMnO4.

The aerobic bacteria count following 28-days refrigeration, as

determined by a SaniCheckAB Test, was 10,000/ml in the Z-KMnO4 enclosed

sample. However, the aerobic bacteria count in the other apple

sample not

exposed to Z-KMnO4 was 10,000,000/ml. The Yeast/Mold

count following 28 days refrigeration in these samples, as determined

by

a SaniCheckYM

Test, was 100,000/ml in both Z-KMnO4 & non-exposed samples,

respectively. Aerobic bacteria growth rate was inhibited by a

factor of 1000 in

an apple sample exposed to Z-KMnO4 as compared to

an apple section from the original parent apple not exposed.

Yeast/Mold growth rate

was numerically equal in Z-KMnO4 and non-exposed samples,

respectively.

Discussion

Whole fruit or fruit juice may be

the source of food-borne illnesses due to pre-harvest contamination

or consumer-neglect from too

long storage. Fresh apples and unpasteurized apple juice receive

little

to no antimicrobial treatment and, despite their health-promoting

image, may transmit or harbor dangerous contaminants. Acid fruit

juices below pH 4.6 were once deemed a minor health threat due

to their high acidity. Furthermore, refrigeration temperatures

(below

5ºC) were thought to resist pathogen growth, until the discovery

that Listeria monocytogenes can

grow in temperatures as low as 2ºC.

Juice spoilage typically occurs as a reflection of the indigenous

microflora, yeast, mold and/or lactic acid bacteria growth. Nonetheless,

the emergence of hitherto unsuspected food pathogens with acid resistance

combined with an increase in susceptible individuals, immunocompromised,

chronically ill, the very young and very elderly, has dramatically

changed this picture. Safety must always take precedent with strict

limits on production, harvest, transportation, storage, manufacture,

processing, labeling and distribution. These are incorporated into

Good Agricultural Practices (GAPs) and Good Manufacturing Practices

(GMPs) with Hazard Analysis and Critical Control Point (HACCP) procedures

being applied throughout the food chain. These will be emphasized

as appropriate. The National Food Processors Association (NFPA) has

considered several options including current Good Manufacturing Practice

(GMP) regulations. One of NFPA's officers wrote, "The

only means of assuring that juice did not contain potentially pathogenic

microorganisms was to include a microbial control step that has been

scientifically proven to be effective in providing a level of protection

equivalent to pasteurization in the process. Two percent of all juice

products are not pasteurized or otherwise treated. Illness attributable

to raw juice or juice includes imported frozen raw (unpasteurized)

Mamey puree (13 cases, typhoid fever—Salmonella), raw apple

juice in Canada (E. coli 0157:H7), raw orange juice in Australia

(435 cases—Salmonella), raw orange juice from Arizona (300

cases—Salmonella muenchen in 20 states) and raw apple juice

in Tulsa, Oklahoma (9 cases—E. coli 0157:H7). Only a microbial

kill step applied to harvested raw fruit and/or juice itself can

ensure that potentially pathogenic microorganisms are eliminated.

Sorting and washing of fruit should be standard practice in all Good

Manufacturing Practice operations for juice production but cannot

be relied upon to ensure the complete removal of pathogenic microorganisms.

While theoretically possible, achieving an appropriate level of protection

from pathogenic microorganisms without applying some inactivating

treatment to the juice seems technologically infeasible at this time.

Processing methods that may provide an equivalent kill step include

batch and continuous high-pressure processing systems, pulsed electric

fields, ultraviolet light, electron beam treatment, irradiation,

ultra filtration, or use of one or more of the preceding treatments

in combination with an anti-microbial compound" (Matthys

AW).

Potassium permanganate (KMnO4) is a potent antimicrobial

compound, which acts as an oxidizing agent directly reducing the

contaminated

environment of indigenous toxic substances and/or aerobic bacteria.

KMnO4 is so potent that it should not come in direct

contact with humans or food nutrients. The packet-package of 7.5

grams Z-KMnO4 permits

the oxidizing, antimicrobial effect of the compound without transition

or absorption into the adjacent foods stored within the same compartment.

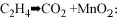

The chemical equation suggested by which ZPCC reduces ethylene

gas and subsequently inhibits fruit ripening rate is through oxidization,

namely as:

(Equation 1) 3CH2 + 2 KMnO4 + H2O = 2MnO2 + 3CH3CHO + 2 KOH

(Equation 2) 3CH3 CHO + 2 KMnO4+ H2O = 3CH3 COOH + 2MnO2 + 2KOH

(Equation 3) 3CH3 COOH + 8KMnO KMnO4 = 6CO2 +

8KMnO2 + 8KOH +

2H2O

(Equation 4) Combining equations 1–3 = 3CH2 CH2 + 12KMnO4

= 12MnO2 + 12KOH + 6CO2

Even if the reaction digresses or does not complete the carbon

dioxide-producing equation, many of the intermediate products

formed are irreversibly

bound to the media or act as a reactant. Such is the case of

the potassium hydroxide (KOH) formed in equations 1 and 2. The

KOH

will react with

the acetic acid formed in equation 2 to produce the potassium

acetate salt (KCOOCH3) through a simple acid-base neutralization

reaction

shown as:

(Equation 5) = CH3 COOH + KOH = KCOCH3 +

H2O, or:

(Equations 1,

2, and 5) = 3CH2CH2 + 4KMnO4 = 3KCOOCH3 +

4MnO2 + KOH =H2O

Conclusion

One 7.5-gram packet of Zeolite-Coated Potassium Permanganate sachet

stored in a plastic louvered container adjacent to an apple section

for 28-days was observed to remarkably reduce ripening rate and aerobic

bacteria growth by a factor of 1000, but failed to reduce the rate

of yeast/mold spore growth. The data observed presents an advantageous

method for reducing aerobic bacteria proliferation in

stored produce,

which is one marker of refrigerated spoilage, which otherwise

may compromise health or increase the risk of food-borne illness.

Z-KMnO4-reduced

produce ripening and subsequent aerobic bacteria contamination

by this intervention should not be employed as a panacea for

all indigenous

microbes, such as yeast/mold spores.

Aerobic Bacteria Count In Two Isolated 25–28

gram Apple Sections

Samples (Post-Refrigeration 28-Days)

| NO E.G.G. SAMPLE |

E.G.G. SAMPLE |

| 10,000,000/ml |

10,000/ml |

Visual View Two Isolated 25–28 gram Apple

Sections

(Post-Refrigeration 28-Days)

| Non-E.G.G. Sample |

E.G.G. Sample |

Extreme Maillard Reaction

Extreme Phenolic Browning |

Mild Maillard Reaction

Mild Phenolic Browning |

Is Ethylene Gas Control KMnO4 Safe?

E.G.G. pellets oxidize the ethylene gas with nascent oxygen (nascent

oxygen is a type of oxygen that oxidizes ethylene gas, molds, rots,

and odors), converting the pellets into manganese dioxide, which

is an organic fertilizer. Since February 2001, the Organic Material

Review Institute for use with Organic food production and the material

approve Ethylene Control E.G.G. for use and the FDA approves ink

that is made in the plastic EGG-content sachets.

Correspondence:

Bill Misner Ph.D.

West 1140 Glass Avenue

Spokane, Washington 99205

509-327-5817

800-336-1977

drbill@e-caps.com

Bibliography

Anderson I. Should potassium permanganate be used in wound care? Nurs

Times. 2003 Aug 5 11;99(31):61. [Abstract]

Anderson WB, Mayfield CI, Dixon DG, Huck PM. Endotoxin inactivation

by selected drinking water treatment oxidants. Water Res. 2003

Nov;37(19):4553–60.

[Abstract]

Bates R.P., Morris J.R., Crandall P.G. Principles and practices of

small—and medium—scale fruit juice processing, FAO

Agricultural Services Bulletin 146.

FAO 2001. [Table 4.1].

Blankenship S. Ethylene: The Ripening Hormone, 16th Annual Postharvest

Conference, Yakima, WA. March 14–15, 2000. Article # PC2000F.

[By permission, courtesy of the author, North Carolina State University,

Horticultural Science Department, Box 7609, Raleigh, NC 27695, [article

by sylvia_blankenship@ncsu.edu]

Brown P, Cathala F, Gajdusek DC. Creutzfeldt Jakob disease. Recommended

precautions for patient management and diagnostic procedures (author's

transl)] Rev Neurol (Paris).

1978 Apr;134(4):277–86. [Abstract]

Buta JG, Moline HE, Spaulding DW, Wang CY. Extending storage life of

fresh-cut apples using natural products and their derivatives. J

Agric Food Chem. 1999 Jan;47(1):1–6. [Abstract]

Han JH, Department of Food Science, Faculty of Agricultural & Food

Sciences, University of Manitoba, Winnipeg, MB, Canada—R3T 2N2

Tel: (204) 474–9295, by permission, courtesy of the author, Professor

J.H. Han. [Article]

Karaivanov L. Effect of physical and chemical factors on Pasteurella

multocida bacteriophages] Vet Med Nauki.

1976;13(4):65–72. [Abstract]

Lang MM, Ingham SC, Ingham BH. Verifying apple cider plant sanitation

and hazard analysis critical control point programs: choice of indicator

bacteria and testing methods. J Food Prot.

1999 Aug;62(8):887–93.

[Abstract]

Mak PP, Ingham BH, Ingham SC. Validation of apple cider pasteurization

treatments against Escherichia coli 0157:H7, Salmonella, and Listeria

monocytogenes. J Food Prot.

2001 Nov;64(11):1679–89. [Abstract]

Matthys AW, Vice President, Regulatory Affairs, National Food Processors

Association (Nfpa). "Comments on Juice Haccp," January

24, 2000. Re: Dockets Management Branch (HFA-305); Food and Drug Administration,

Docket No. 97N-0511; Hazard Analysis and Critical Control Point (HACCP);

Procedures for the Safe and Sanitary Processing and Importing of Juice;

Availability of New Data and Information and Reopening of Comment Period;

64 Federal Register 65669; November 23, 1999. [Article]

Mitcham EJ, Crisosto CH, Kader AA. Apple ‘Red Delicious' Ethylene

Control Recommendations for Maintaining Postharvest Quality. From:

Postharvest Technology Research and Information Center, Department

of Pomology, University of California One Shields Ave., Davis, CA 95616–8683.

Ethylene Control Inc., By permission, courtesy of Dave Biswell, President,

Ethylene Control Inc. July 2001. [Article]

Oyarzabal OA, Nogueira MC, Gombas DE. Survival of Escherichia coli

0157:H7, Listeria monocytogenes, and Salmonella in juice concentrates.

J Food Prot. 2003 Sep;66(9):1595–8. [Abstract]

Parish ME. Public health and nonpasteurized fruit juices. Crit

Rev Microbiol. 1997;23(2):109–19. Review. [Abstract]

Roberts MF, Switzer RL, Schubert KR. Inactivation of Salmonella phosphoribosylpyrophosphate

synthetase by oxidation of a specific sulfhydryl group with potassium

permanganate. J Biol Chem. 1975

Jul 25;250(14):5364–9. [Abstract/Full

JBC Text @: http://www.jbc.org/cgi/reprint/250/14/5364

Slovachevskaia EI, Stasiuk SN, Shenderovskaia LM. [Improved microbiological

control over the products of sublimation drying] Vopr Pitan.

1988 Nov-Dec;(6):60–2.

[Abstract]

Teo AY, Ravishankar S, Sizer CE. Effect of low-temperature, high-pressure

treatment on the survival of Escherichia coli 0157:H7 and Salmonella

in unpasteurized fruit juices. J Food Prot.

2001 Aug;64(8):1122–7.

[Abstract]

Uysal A, Kaaden OR. [Handling of unconventional pathogens] Pathologe.

1993 Dec;14(6):351–4. Review. [Abstract]

Acknowledgements

I wish to acknowledge Biosan Laboratories and WayChem Incorporated

for product donations to this research project:

Aerobic Bacteria and Yeast/Mold measures. Biosan Laboratories donated

a SaniCheckAB & SaniCheckYM Test System For Counting Aerobic Bacteria

and Yeast/Mold. Biosan Laboratories, Inc, 1950 Tobsal Court, Warren

Michigan, 48091–1351.

Zeolite-Coated Potassium Permanganate (Z-KMnO4) packets

were donated by WayChem INC, P.O. Box 1450, 1101 Main Street, Evanston,

Wyoming,

82931.

Disclosure: Neither competing interests nor remunerative relationship

exist between the author and Biosan Laboratories or WayChem Inc, respectively.

|